400Kw Metallurgy Feeding 460mm Cone Crusher Machine

| Minimum Order Quantity: | Negotiate | Price | Negotiate |

|---|---|---|---|

| Packaging Details | Standard container, spare parts will be packed in wooden cases | Delivery Time | 2 months |

| Payment Terms: | T/T, L/C | Supply Ability | 50 sets per Month |

| Place of Origin: | Shanghai, China | Brand Name: | SANME |

|---|---|---|---|

| Certification: | ISO&CE | Model Number: | JC jaw crusher, SMH cone crusher, VC sand maker |

|

Detail Information |

|||

| Application: | Manufacturing Plant, Construction Works , Energy & Mining | Type: | Stone Production Line |

|---|---|---|---|

| Raw Materials: | Granite, Limestone, Concrete, Lime, Plaster | Motor Type: | AC Motor |

| After-sales Service: | Rovided: Video Technical Support, Online Support, Field Installation | Warranty: | 1 Year |

| High Light: |

Standardized Sand Stone Crushing Machine,Granite Plaster Sand Crushing Machine,Sieving Plaster Sand Crushing Machine |

||

Product Description

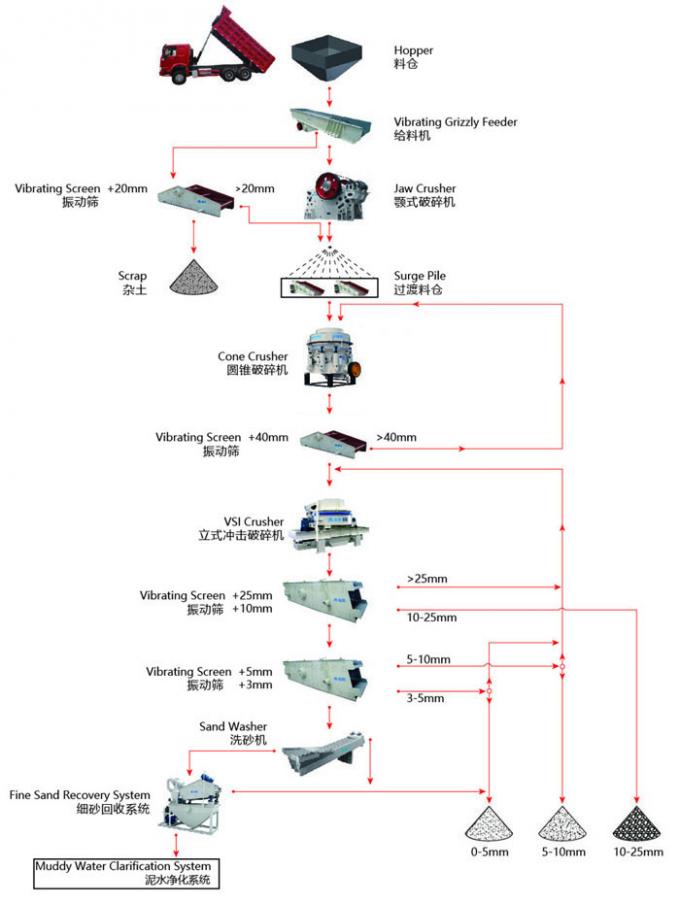

BASIC PROCESS OF PEBBLES SAND MAKING PLANT

The pebbles sand making process is divided into four stages: coarse crushing, medium fine crushing, sand making and sieving.

The first stage: coarse crushing

The pebbles blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing.

The second stage: medium broken

The coarsely crushed materials are screened by vibrating screen and then conveyed by belt conveyor to cone crusher for medium crushing. The crushed stones are conveyed to the vibrating screen through a belt conveyor to sieve out different specifications of stones. The stones that meet the requirements of the customer’s particle size are conveyed to the finished product pile through the belt conveyor. The cone crusher crushes again, forming a closed circuit cycle.

The third stage: sand making

The crushed material is larger than the size of the two-layer screen, and the stone is conveyed to the sand maker machine through the belt conveyor for fine crushing and shaping.

The fourth stage: screening

The finely crushed and reshaped materials are screened by circular vibrating screen for coarse sand, medium sand and fine sand.

Technical description:

1. This process is designed according to the parameters provided by the customer. This flow chart is for reference only.

2. The actual construction should be adjusted according to the terrain.

3. The mud content of the material cannot exceed 10%, and the mud content will have an important impact on the output, equipment and process.

4. SANME can provide technological process plans and technical support according to the actual requirements of customers, and can also design non-standard supporting components according to the actual installation conditions of customers.