400Kw Metallurgy Feeding 460mm Cone Crusher Machine

| Minimum Order Quantity: | Negotiate | Price | Negotiate |

|---|---|---|---|

| Packaging Details | Standard container, spare parts will be packed in wooden cases | Delivery Time | 2 months |

| Payment Terms: | T/T, L/C | Supply Ability | 50 sets per Month |

| Place of Origin: | Shanghai, China | Brand Name: | SANME |

|---|---|---|---|

| Certification: | ISO&CE | Model Number: | HC128,HC139,HC239,HC255,HC359,HC459,HC579,HC679,HC779,HC798,HC898,HC8118,HC8138,HC10158 |

|

Detail Information |

|||

| Raw Materials: | Limestone, Construction Waste | Output Size: | 40-4000t/h |

|---|---|---|---|

| Max Feeding Size Size: | 1900mm | Application: | Mining, Construction, Chemical, Cement, Metallurgical Industries, Etc |

| Weight: | Shown Technical Data | Warranty Of Core Co: | 1 YEAR |

| High Light: |

separator classifier,air classifiers |

||

Product Description

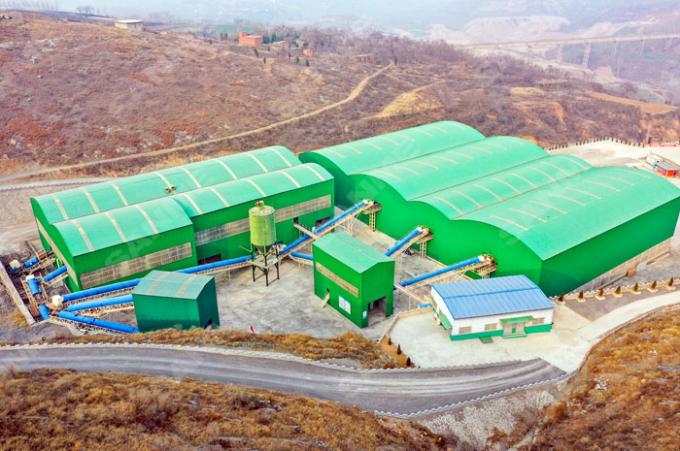

LIMESTONE AGGREGATES PROCESSING

DESIGN OUTPUT

According to customer needs

It is applied for primary, secondary and tertiary crushing of various middle hard materials in the industries of chemical, cement, building and refractory.

Jaw crusher, impact crusher, sand maker, vibrating feeder, vibrating screen, belt conveyor.

Limestone is the trade name of limestone as mining raw material, it has a very wide distribution with abundant reserves. The main component of limestone is CaCO3. Its Moh’s hardness is 3. It is an important road construction material, and also it is an important material for calcinating lime and cement, it is an indispensable high calcium lime to metallurgical industry, after ultrafine grinding, high quality limestone can be widely applied in the production of paper making, rubber, paint, coating, medical, cosmetic, feed, sealing, adhesion, polishing. The compressive strength of limestone is typically about 150 MPa, it belongs to soft rock, and therefore impact crusher is adopted for the production process of limestone production line. The proven Sanme impact crusher is a new type of impact crusher with high efficiency, and is suitable for crushing limestone and sandstone, 95% of crushed material <45mm.

The limestone crushing production line is divided into three stages: coarse crushing, medium fine crushing and screening.

The first stage: coarse crushing

The limestone stone blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing.

The second stage: medium and fine crushing

The coarsely crushed materials are screened by vibrating screen and then conveyed by belt conveyor to cone crusher for medium and fine crushing.

The third stage: screening

The medium and finely crushed stones are conveyed to the vibrating screen through a belt conveyor to separate stones of different specifications. The stones that meet the requirements of the customer’s particle size are conveyed to the finished product pile through the belt conveyor. The impact crusher crushes again, forming a closed circuit cycle.

| Model | Max Feed Size(mm) | Throughput(t/h) | Motor Power(kw) | Overall Dimension(L×W×H)(mm) ( the biggest size ) |

Weight(Motor not included)(t) |

| HC128 | 300 | 40-70 | 37-55 | 3115*1600*2932 | 11.8 |

| HC139 | 400 | 50-80 | 55-75 | 3060*2048*2935 | 14.6 |

| HC239 | 500 | 100-180 | 110-132 | 3095*2048*2970 | 14.7 |

| HC255 | 500 | 100-290 | 132-160 | 3095*2398*2970 | 17.4 |

| HC359Ⅱ | 700 | 180-350 | 200-250 | 3415*2666*3127 | 22.2 |

| HC459 | 750 | 220-450 | 250-315 | 3717*3020*3301 | 27 |

| HC579 | 800 | 250-550 | 400-500 | 3552*3547*3231 | 36.2 |

| HC679 | 1000 | 400-700 | 560-630 | 4019*4064*3652 | 53.2 |

| HC779 | 1300 | 500-850 | 630-800 | 4785*4338*4849 | 79 |

| HC798 | 1300 | 750-1100 | 800-1250 | 4825*4838*4849 | 90.8 |

| HC898 | 1500 | 1000-1500 | 1000-1600 | 5382*5445*5454 | 112.8 |

| HC8118 | 1600 | 1500-2000 | 1400-2000 | 5382*5945*5454 | 135.5 |

| HC8138 | 1600 | 1800-2500 | 1600-2100 | 5348*6527*5454 | 158.8 |

| HC10158 | 1900 | 3600-4000 | 2800-3150 | 6120*7210*6250 | 212.3 |

| Model | Max Feed Size(mm) | Throughput(t/h) | Motor Power(kw) | Overall Dimension(L×W×H)(mm) ( the biggest size ) |

Weight(Motor not included)(t) |

| HSI379 | 350 | 240-460 | 250-280 | 3271*3527*2730 | 23.23 |

| HSI498 | 400 | 275-560 | 280-355 | 3755*3522*2833 | 27.2 |

| HSI5118 | 450 | 375-825 | 500-710 | 3552*4547*2746 | 36.2 |

| HSI6118 | 500 | 600-900 | 800-900 | 3733*5272*3306 | 56.2 |

| HSI7138 | 500 | 875-1490 | 900-1250 | 4785*5838*4120 | 78 |

LIMESTONE AGGREGATES PROCESSING PROJECT CASE