400Kw Metallurgy Feeding 460mm Cone Crusher Machine

2025-9-9

The specifications and capacity of jaw crushers vary depending on the model. The following is a detailed analysis:

1. Specifications and Dimensions

Jaw crusher specifications are typically expressed as feed opening width (B) x length (L). Jaw crushers can be divided into three categories based on size:

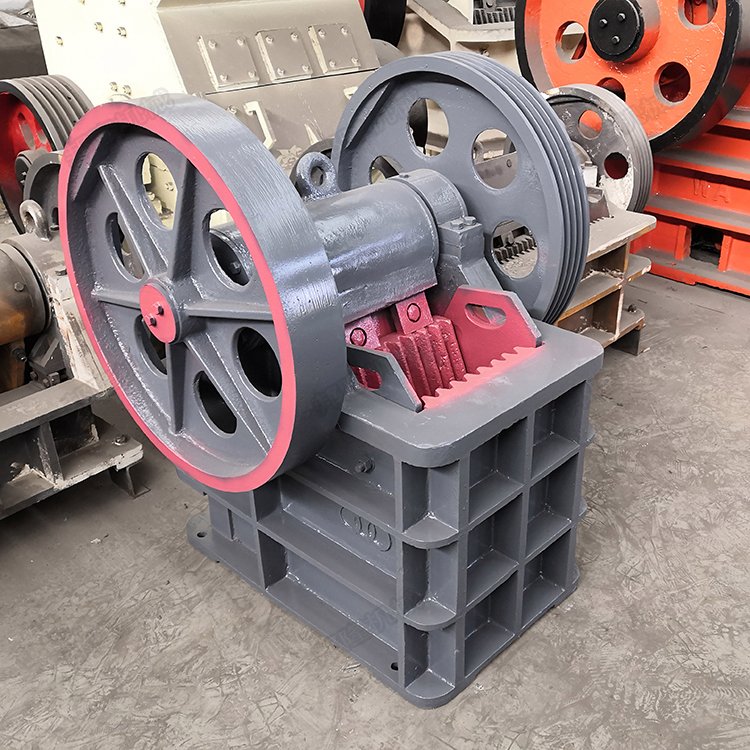

Small Crusher

Feed opening width: ≤500mm

Representative models: PE-200×300, PE-250×400

Features: Compact structure, suitable for laboratories, small mines, or construction waste processing.

Dimensional examples:

PE-200×300: Feed opening 200×300mm, external dimensions 915×780×990mm.

PE-250×400: Feed opening 250×400mm, external dimensions 1380×930×600mm.

Medium-sized crusher

Feed opening width: 500mm-600mm

Representative models: PE-400×600, PEX-250×1000

Features: Balances processing capacity and footprint, suitable for medium-sized mines or building materials plants.

Dimensional examples:

PE-400×600: Feed opening 400×600mm, external dimensions 1730×1730×1630mm.

PEX-250×1000: Feed opening 250×1000mm, external dimensions 2500×1000×2100mm (select models).

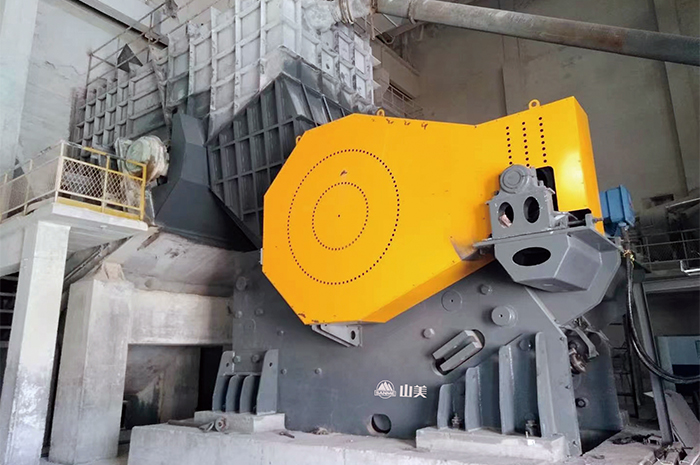

Large-sized crusher

Feed opening width: ≥600mm

Representative models: PE-600×900, PE-900×1200, PE-1200×1500

Features: High processing capacity, suitable for open-pit mines or large-scale building materials production. Example dimensions:

PE-600×900: Feed opening 600×900mm, external dimensions 2190×2206×2300mm.

PE-900×1200: Feed opening 900×1200mm, external dimensions 3800×3166×3045mm.

PE-1200×1500: Feed opening 1200×1500mm, external dimensions 4200×3300×3500mm (select models).

2. Processing Capacity Range

Processing capacity is affected by model, material properties, and discharge opening adjustment. The specific range is as follows:

Small Crusher

Processing Capacity: 0.2-6 tons/hour

Typical Models:

PE-200×300: 2-6 tons/hour

PE-250×400: 3-13 tons/hour

Applicable Applications: Laboratory sample preparation, small gravel pits. Medium-sized Crusher

Processing Capacity: 10-50 tons/hour

Typical Models:

PE-400×600: 15-40 tons/hour

PEX-250×1000: 10-32 tons/hour

Applicable Applications: Coarse Crushing in Medium-sized Mines, Construction Waste Recycling.

Large Crusher

Processing Capacity: 50-500 tons/hour and above

Typical Models:

PE-600×900: 50-180 tons/hour

PE-900×1200: 220-450 tons/hour

PE-1200×1500: 250-500 tons/hour

Applicable Applications: Primary Crushing in Open-Pit Mine, Raw Material Crushing in Large Cement Plants.

3. Key Parameters

Feed Inlet Size: Determines the maximum feed size (usually 80%-90% of the feed inlet width). Discharge opening adjustment range: This affects the discharge particle size (e.g., the PE-600×900 can be adjusted between 65 and 160 mm).

Eccentric shaft speed: Higher speeds improve crushing efficiency, but a balance must be struck between energy consumption and wear (e.g., 260 rpm for the PE-200×300 and 90–110 rpm for the PE-900×1200).

Motor power: Power is positively correlated with processing capacity (e.g., 7.5 kW for the PE-200×300 and 132 kW for the PE-900×1200).

IV. Selection Recommendations

Based on material size:

For small projects, choose the PE-200×300 or PE-250×400;

For medium-sized projects, choose the PE-400×600 or PEX-250×1000;

For large projects, choose the PE-600×900 or higher. Based on discharge requirements:

When fine crushing is required, choose a model with a narrow discharge opening adjustment range (such as the PEX series fine crushing jaw crusher).

Based on site constraints:

When space is limited, a compact design is preferred (such as the PE-250×400, which measures only 1380×930×600mm).