400Kw Metallurgy Feeding 460mm Cone Crusher Machine

2025-9-3

Common primary crushers (coarse crushing equipment) are primarily used to reduce bulk materials (such as ore, rock, and construction waste) to medium-sized particles (typically 100-300 mm), providing suitable feed for subsequent secondary and fine crushing. The following are several common types of primary crushers and their characteristics:

1. Jaw Crusher

Principle: The material is crushed by the periodic opening and closing of the movable and static jaws.

Features:

Simple structure, reliable operation, and easy maintenance.

High crushing ratio (large feed opening and adjustable discharge particle size).

Suitable for materials of varying hardness (such as granite, limestone, and iron ore).

One of the most commonly used equipment for primary crushing.

Applications: Mining, metallurgy, building materials, and chemical industries.

2. Gyratory Crusher

Principle: The main shaft rotates, driving the crushing cone in a gyratory motion, continuously crushing the material. Features:

High processing capacity (suitable for large mines and quarries).

High crushing ratio, uniform output particle size.

The equipment is tall, resulting in high installation and transportation costs.

Applications: Large open-pit mines, aggregate production, etc.

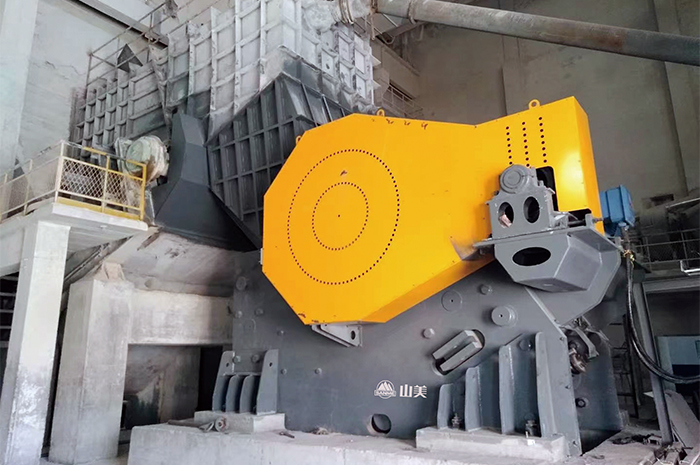

3. Hammer Crusher

Principle: High-speed rotating hammers impact and crush materials.

Features:

Simple structure, high crushing ratio, and high output.

Suitable for brittle materials with low to medium hardness (such as limestone, coal, and gypsum).

The hammers wear quickly and require regular replacement.

Applications: Building materials, chemicals, and power generation industries.

4. Impact Crusher

Principle: High-speed rotating rotor drives hammers to impact and crush materials, which then rebound from the impact plates and become crushed again.

Features:

High crushing ratio, uniform output particle size, and good particle shape (cubic).

Suitable for materials with a hardness below medium (such as limestone and gangue). Primary crushing requires use with a model with a large feed opening.

Applications: Mining, construction, chemical, and other industries.

5. Cone Crusher (some models can be used for primary crushing)

Principle: The material is crushed by the rotating motion of the crushing cone.

Features:

Usually used for secondary and fine crushing, but some coarse-crushing cone crushers (such as the HP series and S series) can also be used for primary crushing.

High processing capacity, stable operation, and a high degree of automation.

Suitable for high-hardness materials (such as granite and basalt).

Applications: Large-scale mining, aggregate production, etc.

6. Roller Crusher

Principle: The material is crushed by two counter-rotating rollers.

Features:

Simple structure, small footprint.

Suitable for low-to-medium-hardness materials (such as coal, limestone, and clay).

Low crushing ratio, usually requires use with other crushers.

Applications: Coal, building materials, chemical, and other industries.

7. Mobile Crusher

Principle: A primary crusher (such as a jaw or impact crusher) is integrated into a mobile chassis, enabling flexible mobility and on-site crushing.

Features:

No fixed installation required, allowing for quick transfer to different work sites.

Suitable for applications such as construction waste disposal and open-pit mining.

Applications: Urban demolition, mining, road construction, etc.

Selection Recommendations:

For high-hardness materials (such as granite and iron ore): Jaw crushers or gyratory crushers are preferred.

For medium-to-low-hardness materials (such as limestone and coal): Hammer, impact, or roller crushers are recommended.

For large mines or high-production requirements: Gyratory crushers or large jaw crushers are recommended.

For high flexibility requirements: Mobile crushers are recommended.

The most suitable primary crushing equipment can be selected based on the material characteristics, production requirements, and budget.