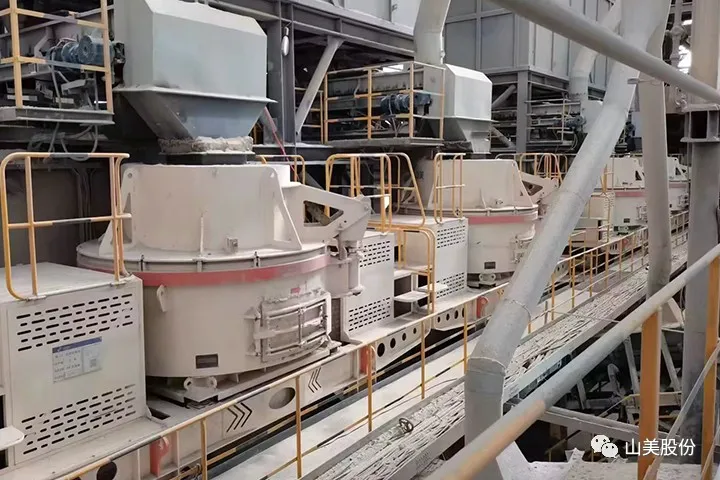

400Kw Metallurgy Feeding 460mm Cone Crusher Machine

2025-8-28

A centrifugal crusher is a highly efficient mechanical device that utilizes centrifugal force to crush materials. Its core feature is that the high-speed rotating rotor accelerates and throws the material, causing it to violently collide with fixed or movable crushing components (such as impact plates and liners), thereby pulverizing the material. The following is a detailed description:

I. Working Principle

Centrifugal Drive

The motor drives the rotor at high speed (typically several hundred to several thousand rpm). After entering the crushing chamber through the feed inlet, the material is accelerated by the rotor’s ejector discs or hammers, achieving extremely high linear velocities (up to tens of meters per second).

Impact Crushing

The accelerated material strikes the impact plate, liner, or another layer of material within the crushing chamber at high speed, breaking it apart through the impact force. Some models also feature a laminated crushing zone, which further refines the particles through mutual compression.

Discharge Control

The crushed material is discharged through a sieve plate or discharge port. The size of the sieve aperture determines the particle size of the final product. Some models utilize adjustable sieve plates or air separation devices for particle size classification.

2. Structural Components

The rotor system, consisting of the main shaft, slinger plate, and hammers or plate hammers, is the core power component of the centrifugal crusher and directly determines the acceleration and crushing energy of the material.

The crushing chamber, consisting of impact plates and liner plates, creates a space for material collision and rebound. Its shape and material influence crushing efficiency and wear resistance.

The drive unit, typically a motor with a pulley or coupling, provides the power required for rotor rotation.

The discharge system, consisting of a screen plate, discharge port, and adjustment device, controls product particle size and discharge speed.

3. Main Types

Vertical Shaft Centrifugal Crusher

Features: The rotor is mounted vertically, and material enters the crushing chamber from top to bottom, making it suitable for fine crushing and sand production.

Applications: Construction aggregate and manufactured sand production.

Horizontal Shaft Centrifugal Crusher

Features: The rotor is mounted horizontally, and material enters the crushing chamber horizontally, making it suitable for secondary and coarse crushing.

Applications: Ore crushing in the mining and metallurgical industries.

Compound Centrifugal Crusher

Features: Combines impact crushing and laminated crushing to improve energy efficiency. Applications: Fine crushing of high-hardness materials such as cement clinker and quartz stone.

4. Performance Advantages

High Efficiency and Energy Saving

Centrifugal force imparts high kinetic energy to the material, resulting in a high crushing ratio (up to 40 or more) and low specific energy consumption.

Excellent Product Shape

Through repeated collisions and rebounds, the product is cubic with low flake content, making it suitable for concrete aggregates.

Strong Adaptability

Can handle medium-hard to ultra-hard materials (such as granite and basalt) and is insensitive to moisture content.

Compact Structure

Small footprint, easy installation and maintenance, suitable for mobile crushing plants.

5. Application Areas

Construction Industry: Manufactured sand production, concrete aggregate preparation.

Mining Industry: Coarse, secondary, and fine crushing of metal and non-metallic ores.

Metallurgy Industry: Furnace charge crushing, refractory material processing.

Chemical Industry: Crushing fertilizers and glass raw materials.