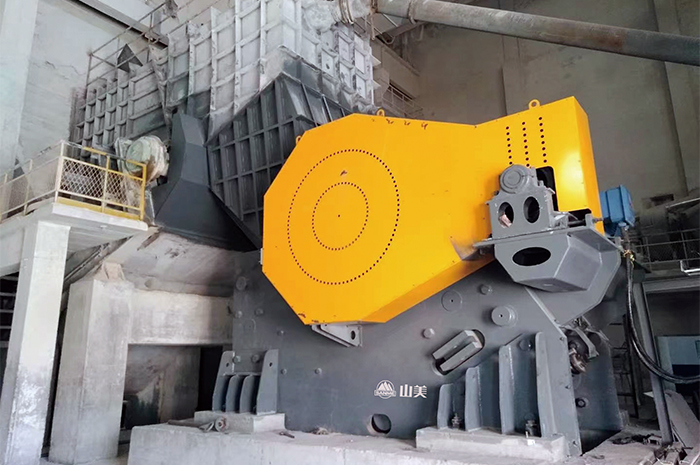

400Kw Metallurgy Feeding 460mm Cone Crusher Machine

2025-6-19

As the core technology system of modern sand and gravel aggregate production, the technical advantages of crushing and sand production line are concentrated in five dimensions: high efficiency and energy saving, intelligent control, environmental protection compliance, excellent finished product quality and modular design. The following is a specific analysis:

1、High efficiency and energy saving technology

Combination of laminated crushing and impact crushing

Using laminated crushing equipment such as jaw crusher and cone crusher to work together with impact sand making machine, by optimizing the crushing cavity type and speed design, energy consumption can be reduced by 20%-30%. For example, a granite production line in Guangdong reduces unit energy consumption by 25% compared with traditional processes by combining multi-cylinder hydraulic cone crusher and vertical shaft impact crusher.

Frequency conversion control system

Equipped with intelligent frequency converter, it adjusts the motor power in real time according to the hardness, humidity and feed amount of the material to avoid no-load energy consumption. Taking the production line with an output of 300 tons per hour as an example, frequency conversion control can reduce power consumption by 15%-20%.

2、Intelligent control technology

Internet of Things remote monitoring

The temperature, vibration, output and other data of the equipment are collected in real time through sensors and uploaded to the cloud platform. For example, a company shortened the equipment failure response time to within 30 minutes through a remote monitoring system, and reduced annual downtime by 40%.

Automated material distribution and grading adjustment

Adopt intelligent material distribution valves and vibrating screen control systems to automatically adjust the finished sand grading according to market demand. For example, a production line can simultaneously produce 0-5mm machine-made sand, 10-20mm crushed stone and 20-30mm aggregate, and the grading error is controlled within ±2%.

3、Environmental protection technology

Dry and wet process optimization

Depending on the characteristics of different materials, dry dust removal (such as pulse bag dust collector, dust emission ≤10mg/m³) or wet sand washing (circulating water utilization rate ≥90%) is adopted. For example, a production line in Guangdong controls the noise below 75dB through the design of closed steel structure workshop and sound insulation cotton.

Resource utilization of solid waste

Equipped with tailings recovery equipment, the stone powder content is controlled at 3%-15%, realizing the recycling of solid waste such as construction waste and tailings. For example, a company uses construction waste to produce recycled aggregates, with an annual processing capacity of 2 million tons, reducing the amount of natural sand mined by 50%.

4、Product quality advantages

Grain shape optimization technology

Through the crushing principle of “stone hitting stone” or “stone hitting iron”, the produced machine-made sand has a shape close to a cube, with a needle-like content of ≤5% and a crushing value of ≤10%. For example, after a high-speed rail project used impact crushing to make sand, the concrete strength increased by 15%-20%.

Precise grading control

Using multi-stage vibrating screens and intelligent material distribution systems, the fineness modulus of the finished sand can be flexibly adjusted within the range of 2.3-3.0 to meet the C30-C60 concrete ratio requirements. For example, after a ready-mixed mortar plant used machine-made sand, the workability of the mortar increased by 30% and the risk of cracking decreased by 25%.

5、Modularity and flexibility

Mobile crushing station

Integrated feeding, crushing, screening, conveying and other modules, can quickly transfer operations. For example, a mining company uses a mobile crushing station to reduce material transportation costs by 30% and increase production efficiency by 40%.

Customization of fixed production lines

Design a stepped or flat layout according to site conditions to support the expansion of production capacity from 50 to 2,000 tons per hour. For example, a large hydropower station project adopts modular design, shortening the construction period to 3 months, saving 50% of time compared to traditional processes.