400Kw Metallurgy Feeding 460mm Cone Crusher Machine

2025-6-6

The working principle of jaw crusher hydraulic system is mainly based on hydraulic technology to achieve discharge port adjustment and overload protection. The following is a detailed description:

Composition and function of hydraulic system

The hydraulic system of jaw crusher consists of two groups of hydraulic cylinders: main hydraulic cylinder and auxiliary hydraulic cylinder. Both use two parallel single piston rod hydraulic cylinders with fixed cylinder barrels. The main hydraulic cylinder is responsible for pressure support and overload protection, while the auxiliary hydraulic cylinder is used for discharge port size adjustment. The hydraulic system drives the actuator to complete the crushing operation through the change of pressure energy, and realizes overload protection and automatic lubrication of components through the pressure control valve.

Working principle

Normal crushing operation

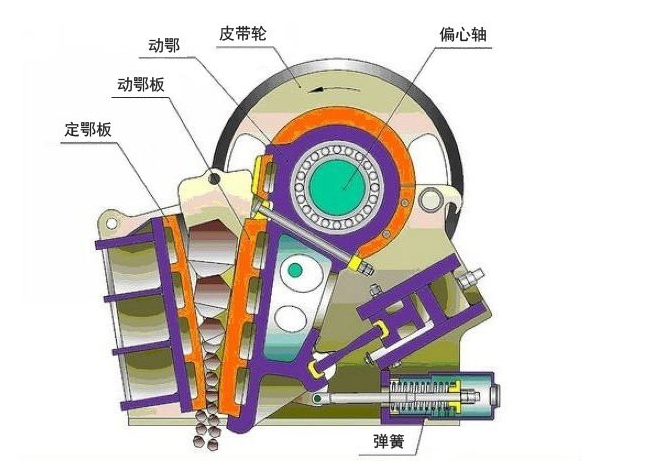

When the material enters the crushing chamber, the motor drives the eccentric shaft to rotate, so that the movable jaw performs periodic reciprocating motion. The material is crushed by squeezing, splitting and bending between the fixed jaw plate and the movable jaw plate. During the crushing process, the hydraulic system provides pressure support to ensure the stability of the crushing chamber. When the movable jaw leaves the fixed jaw, the crushed material is discharged from the discharge port due to its own weight, realizing continuous crushing operation.

Discharge port adjustment

The hydraulic system adjusts the discharge port size by lifting the jaw plate. The auxiliary hydraulic cylinder drives the actuator to change the discharge port size in real time according to production needs to ensure that the crushing particle size meets the requirements.

Overload protection

When non-crushed objects (such as metal blocks) enter the crushing chamber, the crushing force increases sharply. At this time, the hydraulic system discharges the non-crushed objects by increasing the size of the discharge port to avoid equipment damage. The specific process is: the pressure of the thrust plate on the working cylinder is higher than the thrust that the hydraulic cylinder can provide, the oil pressure in the high-pressure oil chamber of the working cylinder increases instantly, the throttle valve activates the action valve, the system drains oil, and the thrust of the thrust plate is limited, thereby protecting the machine. After the non-crushed objects enter the crushing chamber, due to the large thrust that the working cylinder can provide, the piston moves to the right and retracts, and the crusher discharge port increases accordingly, and the non-crushed objects gradually move downward and are discharged from the discharge port.

Automatic recovery

When the non-crushed objects are automatically discharged, the piston is in the retracted position, the crushing force decreases, the action valve spool returns to the upper limit position, and no longer drains oil to the system. At the same time, the plunger injection pump pumps oil to the system with a large amount of oil under the action of the oil pressure regulating device until the working cylinder piston moves to the left position and the crusher resumes normal working state.