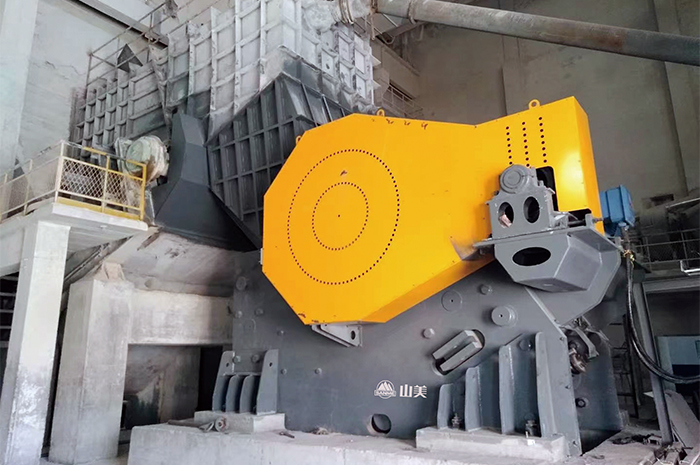

400Kw Metallurgy Feeding 460mm Cone Crusher Machine

2025-5-21

The jaw crusher is a commonly used crushing equipment, mainly used for coarse and medium crushing of various ores and bulk materials. Its main components include the following:

1、Frame

Function: The frame is the supporting structure of the jaw crusher, providing an installation base for other components and bearing various forces during the crushing process.

Features: It is usually made of cast steel or steel plates welded together, with sufficient strength and rigidity to cope with the huge impact force generated during crushing.

2、Fixed jaw plate and movable jaw plate

Fixed jaw plate:

Function: It is fixed on the front wall of the frame and is one of the working surfaces for material crushing.

Features: It is generally made of wear-resistant materials such as high manganese steel, and has a toothed surface to enhance the crushing effect.

Moving jaw plate:

Function: Relative to the fixed jaw plate, it swings back and forth through the drive of the eccentric shaft, and forms crushing actions such as extrusion and grinding with the fixed jaw plate to crush the material.

Features: It is also made of wear-resistant materials, and its swing amplitude and frequency directly affect the crushing efficiency and the particle size of the output material.

3、Eccentric shaft

Function: The eccentric shaft is the driving component of the movable jaw plate, which drives the movable jaw plate to reciprocate by rotating.

Features: It is generally forged with high-quality alloy steel and has high strength and toughness after quenching and tempering. The eccentric shaft is equipped with a pulley or coupling, which is connected to the motor to convert the rotational motion of the motor into the swing of the movable jaw plate.、

4、Movable jaw tie rod spring device

Function:

Movable jaw tie rod: connects the movable jaw plate and the frame, transmits power and limits the movement trajectory of the movable jaw plate.

Spring device: It plays a buffering and protective role. When unbreakable objects (such as iron blocks, etc.) enter the crushing chamber, the spring is compressed, causing the movable jaw plate to retreat to avoid equipment damage; after the unbreakable objects are discharged, the spring returns to its original state, and the movable jaw plate continues to work normally.

Features: The tie rod needs to have sufficient strength and rigidity, and the spring needs to have appropriate elasticity and fatigue life.

5、Adjustment device

Function: It is used to adjust the size of the discharge port to control the particle size of the material after crushing.

Types and features:

Wedge adjustment device: The size of the discharge port is changed by moving the wedge up and down. The adjustment is convenient and flexible, but the adjustment accuracy is relatively low.

Pad adjustment device: The size of the discharge port is adjusted by increasing or decreasing the number of pads. The adjustment range is large, but the adjustment process is relatively cumbersome.

6、Flywheel

Function: Store and release energy to keep the crusher at a stable speed when unloaded, provide additional power when crushing materials, and ensure the smooth progress of the crushing process.

Features: Usually made of cast iron or cast steel, with a large mass, installed at both ends of the eccentric shaft.

7、Transmission components

Function: Transfer the power of the motor to the eccentric shaft to drive the movable jaw plate to move.

Composition and features:

Pulley or coupling: Used to connect the motor and the eccentric shaft to transmit torque. Pulley transmission has the function of buffering and shock absorption, but the transmission efficiency is relatively low; coupling transmission has high transmission efficiency, but the installation accuracy requirements are high.

V-belt or coupling connector: Ensure the reliability and stability of power transmission.

8、Lubrication system

Function: Lubricate the moving parts of the crusher to reduce friction and wear, reduce energy consumption, and extend the service life of the equipment.

Composition and characteristics: Generally includes lubricating oil pump, oil pipe, oil mark, oil filter and other components. The lubricating oil pump delivers lubricating oil to various lubrication points, the oil mark is used to observe the oil level of the lubricating oil, and the oil filter filters impurities in the lubricating oil to ensure the cleanliness of the lubricating oil.