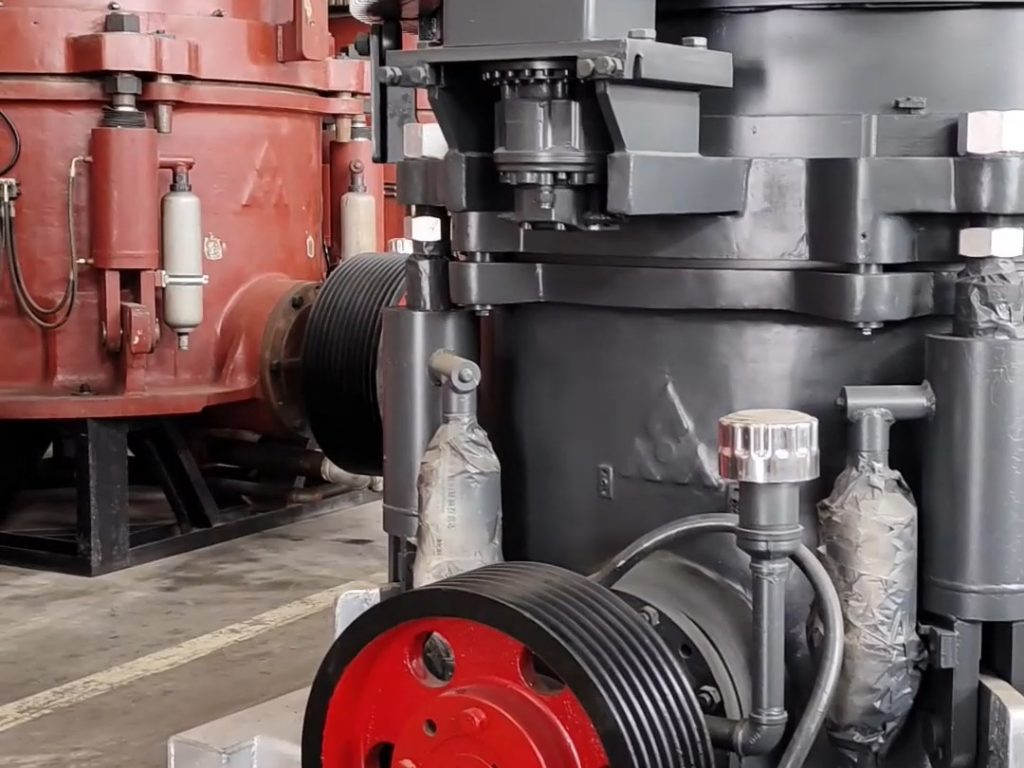

400Kw Metallurgy Feeding 460mm Cone Crusher Machine

2025-5-10

The hydraulic system of a cone crusher is one of the core components of a cone crusher. It undertakes key functions such as protecting equipment, adjusting operating parameters, improving efficiency, and realizing automatic control. Its specific functions are as follows:

1、Overload protection (iron overload protection)

Function: When unbreakable hard objects (such as iron blocks, drill bits, etc.) enter the crushing chamber or the material hardness is too high, the crusher load will increase sharply, which may cause equipment damage. The hydraulic system automatically senses the pressure change through the overload protection device and quickly adjusts the size of the discharge port to allow hard objects to be discharged smoothly and avoid damage to the equipment.

Principle: The hydraulic system monitors the spindle pressure through a pressure sensor. When the pressure exceeds the set value, the hydraulic cylinder pushes the moving cone back to increase the gap of the discharge port. After the hard objects are discharged, the system automatically resets.

Advantages: Effectively prevent equipment damage due to overload, reduce downtime and maintenance costs.

2、Automatic adjustment of the discharge port

Function: The hydraulic system can adjust the size of the discharge port in real time to control the particle size of the discharge material to meet different production needs.

Principle: The hydraulic cylinder pushes the moving cone to move, changing the gap between the moving cone and the fixed cone, thereby adjusting the size of the discharge port.

Advantages: Easy operation, high adjustment accuracy, can quickly adapt to different particle size requirements, and improve production flexibility.

3、Hydraulic locking and adjustment

Function: The hydraulic system fixes the position of the moving cone through the locking device to ensure stable operation of the equipment; at the same time, the eccentricity of the crushing chamber and the gap between the liner can be adjusted to optimize the crushing effect.

Principle: The hydraulic cylinder applies pressure to the moving cone to keep it in stable contact with the fixed cone; by adjusting the pressure of the hydraulic system, the geometric parameters of the crushing chamber can be changed.

Advantages: Improve crushing efficiency, reduce energy consumption, and extend the service life of the liner.

4、Hydraulic cavity clearing (blocking)

Function: When the material in the crushing chamber is blocked, the hydraulic system can quickly clear the crushing chamber and resume production.

Principle: The hydraulic cylinder pushes the moving cone back to increase the gap between the discharge port and discharge the blocked material.

Advantages: Reduce manual intervention, shorten downtime, and improve equipment utilization.

5、Hydraulic lubrication and cooling

Function: The hydraulic system provides lubrication and cooling for the equipment, reduces wear and extends service life.

Principle: The hydraulic oil circulates through the oil pump to lubricate key components such as the spindle and bearings, and takes away heat.

Advantages: Reduce equipment temperature, reduce thermal deformation, and improve operating stability.

6、Automatic control and safety protection

Function: The hydraulic system is linked with the control system to achieve automatic operation and safety protection of the equipment.

Principle: The operating parameters of the equipment (such as pressure, temperature, vibration, etc.) are monitored in real time through sensors, and the hydraulic system automatically adjusts the operating status according to the control signal.

Advantages: Improve production efficiency, reduce manual operation risks, and ensure safe operation of equipment.

7、Energy saving and environmental protection

Function: The hydraulic system reduces energy loss, energy consumption and noise by optimizing power transmission.

Principle: The hydraulic system uses high-efficiency oil pumps and valves to reduce hydraulic oil leakage and energy waste.

Advantages: Meet energy-saving and environmental protection requirements and reduce production costs.